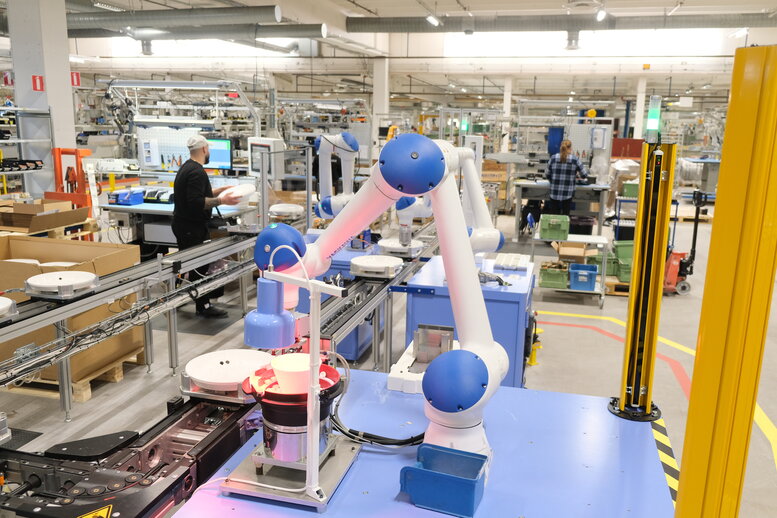

Collaborative assembly application with HC10

Fagerhult Belysning was founded in the mid 1940:s and is now part of the Fagerhult Group, one of Europe's leading lighting companies, with twelve different brands and 4,100 employees around the world. They make first-class lighting solutions that improve people's well-being in professional and public environments such as offices, schools, healthcare, retail and outdoor applications.

- Industrije

- Elektronika

- Consumer goods logistics

- Aplikacije

- Assembly

- Human-Robot Collaboration

- Stranka

- Fagerhult Belysning AB

- Izdelki

- HC - serija

In 2021 three HC10 robots arrived at Fagerhult as an unexpected opportunity to make the most of. Fagerhult was familiar with robotic automation, including five conventional Motoman robots already in operation, but had limited experience of any type of collaborative robots. Aiming to create a productive solution on their own their challenge was: to break down products into suitable assembly tasks for the robots and test, evaluate and create a productive application without external help.

With initial training and support from Yaskawa, Fagerhult’s automation department were able to do all the testing, evaluation, and development of the final application on their own. The robotic assembly includes:

1. assembly (plug/conduit entry)

2. assembly (panel into snap fastener)

3. screwing (securing the driver unit)

4. picking and placing (terminal blocks).

RFID tags are used to keep track on the components to be assembled for each product. Using safety scanners, the robots can alternate between their industrial mode in full speed and a safe collaborative mode.

- More than 240 pcs daily of the high-volume products.

- Improved ergonomics with a reduction of repetitive and tiring manual tasks.

- It is a future proof system, with all the application and programming experience and knowhow remaining within the company.

This inhouse automation approach has increased Fagerhult’s desire to add more robotic automation projects in the future.